Home page||Ship stabilizers||

Tank stabilizers- Generating anti-rolling forces & Ship propulsiom systems

Tank stabilizers (like bilge keels) are virtually independent of the forward speed

of the vessel. They generate anti-rolling forces by phased flow of appropriate

masses of fluid, usually water, in tanks installed at suitable heights and distances

from the ship's centre line.

Fluid transfer may be by open flume or from and to

wing tanks connected by cross ducts. The tank/fluid combination constitutes a

damped mass elastic system having its own natural period and capable of

developing large forces at resonance with the impressed wave motion.

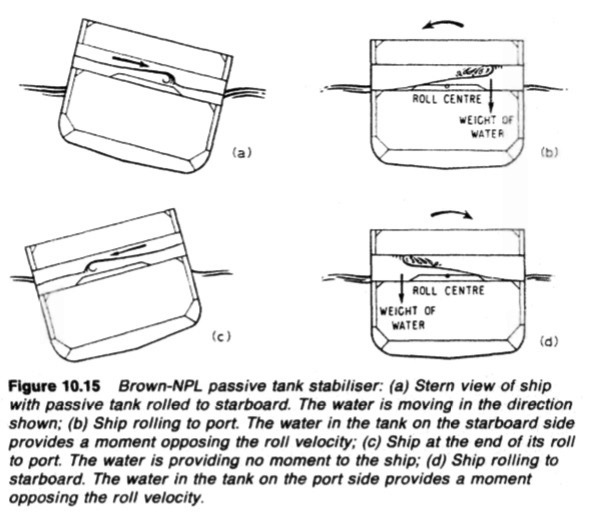

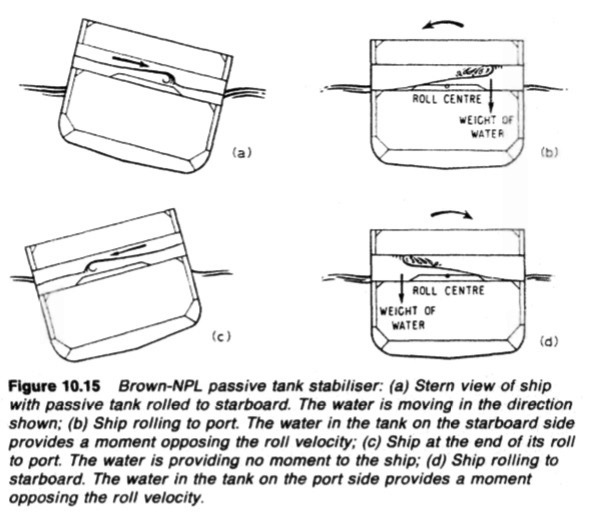

Since the fluid can only flow downhill and has inertia, it cannot start to move

until the ship has rolled a few degrees (Figure 10.15). The natural restoring

forces limit the maximum roll angle and initiate roll in the opposite sense. In the

meantime the fluid continuing to flow downhill, piles up on the still low side

and provides a moment opposing the ship motion. As the ship returns and

passes its upright position, fluid again flows downhill to repeat the process.

The fluid flow tends to lag a quarter of a cycle behind the ship motion, a

phase lag of approximately 90 deg , to generate a continuing stabilizing moment.

This is due, mainly, to the transfer of the centre of gravity of the fluid mass

away from the centre line of the ship. The transverse acceleration of the fluid

generates an inertia force and thereby a moment, about the roll centre, which

reduces the gravity moment when the tanks are below the roll centre and

increases it when they are above.

In practice, tanks may be placed 20% off the

beam below the roll centre without serious loss of performance. Above the roll

centre, other factors associated with the phase of fluid motion prevent

augmentation of the gravity stabilizing power being realized. The phase lag

may be increased, within limits, by placing orifice plates or grillages in the fluid

flow path, to increase the damping.

In the wing tank system the mode of operation is similar to the simple flume

but the tank geometry combined with the dynamic amplification of the flow

tends to make fluid pile up to a greater height at a greater distance from the

ship's centre line to give more effective stabilization. The wing tanks must be of

sufficient depth to accommodate the maximum rise of the fluid without

completely filling them.

The natural period of the fluid is a function of

tank geometry and the volume of fluid contained. It is arranged to be equal to

or slightly less than the lowest natural roll frequency of the ship. Provided the

system has little damping, maximum roll reduction is achieved at resonance

and the roll amplitude/roll period characteristic is virtually a straight line at

about the optimum residual roll characteristic.

Figure : Brown-NPL passive tank stabiliser

Figure 10.15 Brown-NPL passive tank stabiliser: (a) Stem view of ship

with passive tank rolled to starboard. The water is moving in the direction

shown; (b) Ship rolling to port. The water in the tank on the starboard side

provides a moment opposing the roll velocity; (c) Ship at the end of its roll

to port. The water is providing no moment to the ship; (d) Ship rolling to

starboard. The water in the tank on the port side provides a moment

opposing the roll velocity.

Anti-heeling tanks

Container ships and RO-RO (roll onóroll off) vessels are usually fitted with

anti-heel tanks which enable the ship to be kept upright during uneven loading

of cargo. Transfer of liquid from one tank to the other is by pump or

compressed air.

Controlled passive system stabilizing tanks are used in the anti-heeling

arrangements of some ships. The simplest method in this scheme, for

transferring the liquid, makes use of compressed air admitted to the top of

either tank, to force the liquid from one to the other.

Summarized below ship stabilizing system detail guideline:

- Ships bow thrusters-Electric drives, diesel drives, hydraulic drives & white Gill type

Safety is increased when berthing in adverse

weather conditions provided that the required thruster capacity has been

correctly estimated. Transverse thrusters are installed to facilitate the

positioning of some types of workboats.

More .....

- Fin stabilizers and stabilizing systems

The stabilizing power of fins is generated by their movement through the sea and lift' created by the flow of water above and below the 'aerofoil' or hydrofoil shape. When the front edge of the fin is tilted up, water flow across the top of the profile produces lift due to a drop in pressure while a lifting pressure is provided by flow along the underside.More.....

- Folding fin stabilizer & Retractable fin stabilizers-

Housing and extending the fin is achieved by a double acting hydraulic

cylinder connected to the upper part of the trunnion. Power units, control and

sensing equipment are generally similar to other types of stabilizer except that

feed-back of fin angle is accomplished electrically by synchros.More....

- Tank stabilizers

Tank stabilizers (like bilge keels) are virtually independent of the forward speed

of the vessel. They generate anti-rolling forces by phased flow of appropriate

masses of fluid, usually water, in tanks installed at suitable heights and distances

from the ship's centre line.More....

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||