Home page||Ship employment

||

Making Fast and Casting Off safe practice for general cargo vessel

General guidance for mooring and un-mooring operations

During mooring and un-mooring operations a sufficient number of

personnel should always be available at each end of the vessel to ensure a

safe operation. A responsible officer should be in charge of each of the

mooring parties, and a suitable means of communication between the

responsible officers and the vessel's bridge team should be established. If this

should involve use of portable radio, then the ship should be clearly identified

by name to prevent misinterpretation. All personnel involved in such

operations should wear suitable protective clothing

Vessels' heaving lines should be constructed with a `monkey's fist' at

one end. To prevent personal injury, the `fist' should be made only with rope

and should not contain added weighting material.

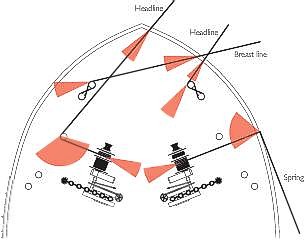

Fig:Mooring arrangement

Areas where mooring operations are to be undertaken should be

clutter free as far as possible. Decks should have anti-slip surfaces provided by

fixed treads or anti-slip paint coating, and the whole working area should be

adequately lit for operations undertaken during periods of darkness.

All equipment used in mooring operations should be regularly

inspected for defects. Any defects found should be corrected as soon as

possible. Particular attention should be paid to the risk of oil leaks from

winches, and surfaces of fairleads, bollards, bitts and drum ends should be

clean and in good condition. Rollers and fairleads should turn smoothly and a

visual check be made that corrosion has not weakened them. Particular

attention is drawn to the need to ensure that pedestal roller fairleads, lead

bollards, mooring bitts etc. are

(a) properly designed to meet all foreseeable operational loads and

conditions,

(b) correctly sited, and

(c) effectively secured to a part of the ship's structure which is suitably

strengthened.

Mooring ropes, wires and stoppers that are to be used in the

operation should be in good condition, Ropes should be frequently inspected

for both external wear and wear between strands. Wires should be regularly

treated with suitable lubricants and inspected for

deterioration internally and broken strands externally. Splices in both ropes

and wires should be inspected regularly to check they are intact. Where wire

rope is joined to fibre rope, a thimble or other device should be inserted in

the eye of the fibre rope. Both wire and fibre rope should have the same

direction of lay.

Ropes and wires which are stowed on reels should not be used

directly from stowage, but should be run off and flaked out on deck in a clear

and safe manner, ensuring sufficient slack to cover all contingencies. If there is

doubt of the amount required, then the complete reel should be run off.

It is often difficult to achieve an ideal mooring layout. Ship's

equipment can be employed to the best advantage if the following general

principles are remembered:-

(a) breastlines provide the bulk of athwartships restraint;

(b) backsprings provide the largest proportion of the longitudinal restraint;

(c) very short lengths of line should be avoided when possible, as such

lines will take a greater proportion of the total load, when movement

of the ship occurs.

Careful thought should be given to the layout of moorings, so that

leads are those most suited without creating sharp angles, and ropes and

wires are not fed through the same leads or bollards. Pre-planning of such

operations is recommended and a risk assessment of the operation should

be completed, especially in cases where the ship is having to use an unusual

or non-standard mooring arrangement.

Personnel should not in any circumstances stand in a bight of rope

or wire. Operation of winches should preferably be undertaken by

competent personnel to ensure that excessive loads do not arise on

moorings.

When moorings are under strain all personnel in the vicinity should

remain in positions of safety, It is strongly

recommended that a bird's eye view of the mooring deck arrangement is

produced (an aerial view from a high point of the ship can be utilised) to

more readily identify danger areas. Immediate action should be taken to

reduce the load should any part of the system appear to be under excessive

strain. Care is needed so that ropes or wires will not jam when they come

under strain, so that if necessary they can quickly be slackened off.

Where a mooring line is led around a pedestal roller fairlead, the `Snap-Back'

Zone area will change and increase in area. Where possible, lines should NOT

be led round pedestals except during the operation of mooring the ship,

thereafter lines should be made up on bitts, clear of pedestals if at all possible.

Information on `Snap-Back' Zones can be found in section

6.3.5 of the Oil Companies International Marine Forum (OCIMF) publication

"Mooring Equipment Guidelines".

Fig: `Snap-Back' Zones

Where moorings are to be heaved on a drum end, one person

should be stationed at the drum end, backed up by a second person backing

and coiling down the slack. In most circumstances three turns on the drum

end are sufficient to undertake a successful operation. A wire on a drum end

should never be used as a check wire.

A wire should never be led across a fibre rope on a bollard. Wires

and ropes should be kept in separate fairleads or bollards.

When stoppering off moorings the following applies:-

(a) Natural fibre rope should be stoppered with natural fibre.

(b) Man made fibre rope should be stoppered with man made fibre stopper

(but not polyamide).

(c) The `West Country' method (double and reverse stoppering) is

preferable for ropes.

(d) Wire moorings should be stoppered with chain, using two half hitches in

the form of a cow hitch, suitably spaced with the tail backed up against

the lay of wire, to ensure that the chain neither jams nor opens up the

lay of the wire.

Mooring to bouy

During mooring and un-mooring operations a sufficient number of

personnel should always be available at each end of the vessel to ensure a

safe operation. A responsible officer should be in charge of each of the

mooring parties, and a suitable means of communication between the

responsible officers and the vessel's bridge team should be established. If this

should involve use of portable radio, then the ship should be clearly identified

by name to prevent misinterpretation. All personnel involved in such

operations should wear suitable protective clothing .

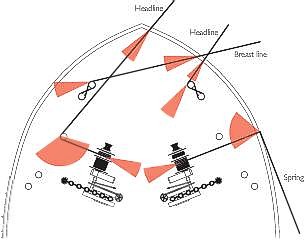

Where mooring to buoys is undertaken from a ship's launch or

boat, personnel engaged in the operation should wear lifejackets and a

lifebuoy with attached lifeline should be kept readily available in the boat.

Fig:Mooring arrangement

Means should be provided to enable a person who has fallen into

the water to climb back on board the launch or boat. If a boarding ladder

with flexible sides is used, it should be weighted so that the lower rungs

remain below the surface.

Where mooring to buoys is undertaken from the ship, a lifebuoy

with attached line of sufficient length should be available for immediate use.

When slip wires are used for mooring to buoys or dolphins, the

eyes of the wires should never be put over the bitts, as at the time of un-

mooring it may not be possible to release the load sufficiently to lift the eye

clear. To prevent accidental slippage of the wire eye(s) over the bitts or

other obstruction the eyes should be seized, partially closing the eye.

Towing - Making fast tugs towline

A number of accidents to persons have occurred during the

relatively simple operation of making fast and letting go of tug's tow lines.

The common factor was that, for various reasons, the tow lines became taut,

causing, for instance, messengers to part and strike ship's crew, and seamens'

hands to become trapped, all of which resulted in major injuries.

Equipment used for towing should be adequately maintained and

inspected before use, as during towing operations excessive loads may be

applied to ropes, wires, fairleads, bitts and connections.

Prior to towing operations being undertaken, the master should

establish suitable means of communication, exchange relevant information

(eg speed of vessel), and agree a plan for the tow with the tug master.

All workers involved should be adequately briefed in their duties

and safety precautions to be taken. They should be equipped with personal

protective equipment including safety helmets and safety shoes.

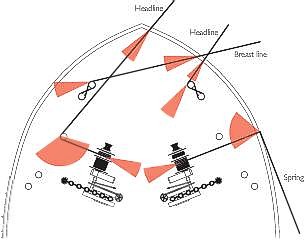

Fig:Mooring arrangement

Workers should, wherever possible, agree with the tug crew the

area where the heaving line is to be thrown to, in order that they move

clear. A messenger should be used to heave the tug's tow line on board by a

winch, and then a stopper used while the eye is placed around the bollard.

Only enough turns of the messenger should be used on the warping drum

end to heave in the tow line. On tankers, do not place the tow line's eye

over the bollard which has the fire wire made fast to it. Take the fire wire off,

if there is no bollard available.

Once the tow is connected, non-essential personnel should keep

clear of the operational area. If anyone is required to remain in this area or

to attend to towing gear during the towing operation, they should take

extreme care to keep clear of bights of wire or rope and the "Snap-Back"

Zone should a line break. Exposure time should be kept to a minimum.

During operations, communications should be maintained

between:-

(a) the towing vessel and both the bridge team and the foredeck of the

vessel under tow; and

(b) the tow party and the bridge team.

In all communications clear identification of the parties communicating

should be used to prevent misunderstandings. The Tug Master should be

kept informed of engine movements, proposed use of thrusts etc. Persons

in charge of the mooring party should monitor the tow line to give warning

to the crew if the tow line should become taut, for whatever reason.

When letting go the tow, no attempt should be made to heave in

the tow line slack before making positive communications with the tug's

crew and they have indicated that they are ready to receive their line. Use

the tug's attached messenger to heave in the slack and then stopper it off

before taking the eye off the bollard. Use turns of the messenger around

the bollard to control the speed at which the tow line goes out

and is retrieved on board the tug. If the tow line is allowed to run

out uncontrolled, it could whiplash, and strike a crewmember,

causing severe injuries.

Further recommendations on towing are contained in

Merchant Shipping Notices.

Other useful articles :

- Rope handling safe procedure

Ropes are made of short fibres that are spun into yarns,

which are then made into flat or twisted strands.

And the strands are spun or braided to make the finished

rope .

More .....

-

Synthetic man-made ropes and hawsers

Although natural fibre ropes are still widely used throughout the marine industry, they have been superseded by synthetic fibres for a great many

purposes. Not only do the majority of synthetic ropes have greater strength

than their natural fibre counterparts, but they are more easily obtainable

and at present considerably cheaper.

More .....

-

Natural fibre rope

All natural fibre rope is manufactured from manilla, sisal, hemp, coir, cotton

or flax fibres.The process of manufacture consists of twisting the fibres

into yarns and turning the yarns in an opposite direction to establish the

strands.

More .....

- Prepare cargo holds prior loading

Washing is always carried out after the compartment has been swept. Drying time for washed compartments must be allowed for, before loading the next cargo; this time will vary with the climate, but two to three days must be expected.

More .....

- Strength and stability of the Lifting appliances

The vessel's structure, crane, derrick or other lifting device and the supporting structure should be of sufficient strength to withstand the loads

that will be imposed when operating at its maximum load moment .

More .....

- Anchoring safe practice

Prior approaching an area for anchoring ships master should investigate fully a suitable anchoring position and conduct a planned approach including speed reduction in ample time and orienting the ships head prior anchoring to same as similar sized vessels around or stem the tide or wind whichever is stronger . Final decision to be made on method of anchoring to be used , the number of shackles , the depth of water, expected weather and holding ground. .

More .....

- MacGregor single-pull weather-deck hatch cover

Hatch covers are used to close off the hatch opening and make it

watertight. Wooden hatch covers, consisting of beams and boards over

the opening and covered with tarpaulins, were once used but are no

longer fitted. Steel hatch covers, comprising a number of linked steel

covers, are now fitted universally. Various designs exist for particular

applications, but most offer simple and quick opening and closing,

which speed up the cargo handling operation..

More .....

- Cargo holds access arrangement

The access shall be separate from the hatchway opening, and shall be by a stairway if possible. A fixed ladder, or a line of fixed rungs, shall have no point where they fill a reverse slope

.

More .....

-

Lay of Ropes and hawsers - Small Stuff descriptions

The lay of rope is a term used to describe the nature of the twist that produces the complete rope .The most common form of rope at sea is known as ‘hawser laid rope’ comprising three strands laid up right- or lefthanded.

More .....

- Stresses in ship structures and how to mitigate

Heavy weights tend to cause a downward deflection of the deck area supporting the load .This subsequently produces stresses, with

consequent inward and outward deflections of supporting bulkheads,

depending on the position of initial loading .

More .....

- Lifting appliances - Maintenance, testing, controls & safety measures

When there is any suspicion that any appliance or item of

equipment may have been subjected to excessive loads, exceeding the Safe

Working Load (SWL), or subjected to treatment likely to cause damage, it

should be taken out of service until it can be subjected to a thorough

examination by a competent person.

More .....

- Safe operation of Lifting appliances and gears

All lifting operations must be properly planned, appropriately

supervised and carried out to protect the safety of workers.

More .....

Machinery system main info pages

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship employment

||

Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||