Home page||Ship employment

||

Purpose of assigning loadlines on board general cargo ships

How to assign loadlines ?

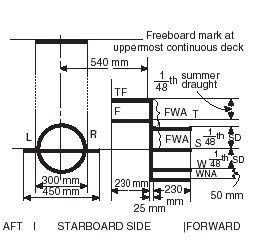

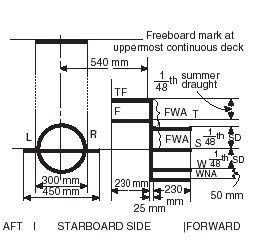

Fig:Loadlines

Fig:Loadlines

Loadlines are marks punched into and painted on the sides of general cargo ships. These Plimsoll marks take their name from the

politician Samuel Plimsoll . The Merchant

Shipping Act 1876, gave the Department of Trade and Industry UK, as we

now know it, the right of inspection, to ensure that a vessel should not be

overloaded beyond her Plimsoll mark or line.

The assigning of the vessels loadline and the issue of the Certificate is the

responsibility of the Marine Authority of the country. The loadline survey being conducted

in accord with the International Conference on Load Lines, 1969,

the Merchant Shipping (Survey and Certification) (Amendments) Regulations

2000 and the 1988 SOLAS and Load Line Protocols.

All seagoing Cargo ships need to carry loadline certificate :

# To ensure minimum freeboard

# Max draught allowed on ship

# Sufficient reserve buoyancy of vessel

# Avoid vessel overloaded with cargo

Period of Load line certificate : 5 years

The calculation regarding the freeboard, and consequently the position

of the loadlines, will be dependent on the type of vessel and its length,

ships being divided into two types ‘A’ and ‘B’.

Type ‘A’ – Vessels designed to carry only liquid, bulk cargoes, e.g. tankers.

Type ‘B’ – All other vessels not governed by the Type ‘A’ definition.

With the exception of pleasure yachts, warships and the like, the majority of vessels of all maritime nations over 80 net registered tons are obliged to be marked with statutory loadlines, to ensure

that they are not overloaded.

A loadline certificate must be displayed in a prominent place aboard the

vessel.The certificate is valid for five years, but an annual survey is held to

ensure that the conditions of assignment and the loadline marks remain

unchanged.

Should the loadline be submerged through the overloading of the vessel,

so contravening the regulations then the master or owner is liable to a fine

as set by the administration for every cm or part of 1 cm overloaded.The

upper edge of loadline marks are the recognised mark levels.The loadline

itself is punched into the shell plate and painted a distinctive

colour, usually white or yellow on a dark background.

Many vessels now employ computer loading

programmes to establish disposition of cargo,

ballast and stores.

Such software can be beneficial and avoiding vessel being overloaded.

It is a statutory requirement that the ship is not to be loaded beyond the limits specified in its loadline certificate.

The appropriate loadline marks on the ship side must not be submerged at any time during the seagoing voyage.

End hold trimming to maximise cargo carrying capacity and bring the ship down to her marks- is to be avoided, as it may result in the overloading of end holds beyond allowable limits, increasing local and global stresses.

International Convention On Load Lines

The Concentrated Inspection Campaign (CIC) on Structural Safety and the International Convention on Load Lines was carried out in the Tokyo MOU region from September 1, 2011 to November 30, 2011. This campaign was conducted jointly with the Paris MOU while regional PSC regimes of the Vina del Mar Agreement, the Indian Ocean MOU, the Mediterranean MOU and the Black Sea MOU also participated in the campaign.

The 18-member authorities carried out a total of 7,534 PSC inspections, which included 5,901 CIC inspections. During the campaign, 2,929 CIC-topic related deficiencies were found with 83 ships out of a total of 346 detentions being detained for CIC related deficiencies. The detention rate for the CIC is 1.41% while the overall detention rate for the period is 4.59%.

The highest number of inspections were carried out on ships under the flags of Panama 1,900 (32.20%), Hong Kong (China) 468 (7.93%), Liberia 366 (6.20%) and Singapore 347 (5.88%). The flags with the highest number of CIC related detentions were Cambodia 23 (27.71%), Panama 21 (25.30%), Sierra Leone 7 (8.43%) and Vietnam 7 (8.43%). Bulk carriers were the ship type with the highest number of CIC inspections which accounted for 1,898 (32.16%), followed by general cargo vessels 1,565 (26.52%) and container vessels 983 (16.66%).

The most significant deficiencies found during the campaign were related to the protection of openings (Ventilators, air pipes, casings) 554 (18.91%), followed with casing (Hatchway-, portable-, tarpaulins, etc) 273 (9.29%) and Doors 245 (8.36%). The Port State Control Committee will consider the final analysis of the campaign's results in April 2012.

Other useful articles :

- Assigning loadlines marks

Loadlines are marks punched into and painted on the sides of general cargo ships.The assigning of the vessels loadline and the issue of the Certificate is the

responsibility of the Marine Authority of the country. .

More .....

-

Cargo ships Loaded Condition

closely monitor the ship's condition during cargo

operations to ensure that if a significant deviation from the agreed loading/unloading

plan is detected all cargo and ballast operations must STOP..

More .....

-

Packing a container recommended method

Packing a container should always be done on level plane either on the ground,on a railcar, or on a trailer. In the case of a trailer, care should be taken to ensure the trailer cannot tip whilst being packed especially if a forklift truck is being used. If necessary the trailer should be propped. Brakes should be securely applied and wheels choked.

More .....

- Packing principles relating to cargo in containers

Where relevant, stowing should be carried out in a sequence which will permit

rapid checking and storage operations during and after unloading. Should the

consignment include cargo subject to customs pre-entry procedures, customs

examination would be made easier and unloading avoided if the cargo were

stowed at the end of the container by the door.

More .....

- Container Securing guidance

Containers have very little strength in any direction other than vertically

through the corner posts thus it is necessary to provide substantial support

to the containers when they are on the ship. Stowage of containers is with

their longer dimension fore and aft since the ship motion transmitted to

cargo is greater in rolling than pitching and it is therefore prudent to limit

any possible cargo movement within the container to the shorter transverse

dimension.

More .....

- Trim and stability booklet for cargo ships

Contain either curves of form or hydrostatic tables and stability and trim characteristics for various conditions of loading

.

More .....

- Broken stowage? Cargo ships guideline

The access shall be separate from the hatchway opening, and shall be by a stairway if possible. A fixed ladder, or a line of fixed rungs, shall have no point where they fill a reverse slope

.

More .....

-

Ship type, design and facilities for cargo

Cargo gear is designed for speed and flexibility for handling breakbulk, palletized, or container cargo. Various combinations of derricks,

winches, and deck cranes are used for the handling of cargo. Cranes are fitted on many vessels to reduce manpower requirements. Some ships

have special heavy-lift derricks that may serve one or more holds. Booms are rigged for either yard and stay (burton) or swinging-boom

operation.

More .....

- Cargo ships structural plans- how to use them

Structural plans, sometimes called scantlings plans, show dimensions of the ships framing and plating. The midships section drawing, generally available for all ships

More .....

Machinery system main info pages

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship employment

||

Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||

Fig:Loadlines

Fig:Loadlines