Home page||Ship employment

||

Modern cargo ships - Basic knowledge , ship type, design and facilities for cargo

Basic knowledge of general cargo ships

Modern dry cargo ship designs maximize hold space . A typical mid-size ship may have five or six holds; three or four

forward of the machinery space and superstructure, and one or two aft. The machinery spaces and superstructure are usually located about threequarters

aft. Older designs typically have three holds forward of the superstructure and two aft. Holds aft of the accommodation and machinery

spaces improve the trim of the vessel when partially loaded, and provide the ship with sufficient draft aft for stability and propeller immersion.

Small freighters often have machinery and accommodation spaces aft of all cargo holds. Deadweight of modern general cargo liners ranges

from 9,000 to 25,000 tons; speeds range from 17 to 22 knots. Tramps are typically smaller and slower, with speeds ranging from 12 to 18 knots.

The speed-to-length ratio is generally 0.87 or less as higher ratios are usually not economical. Laden drafts are as deep as channels to the

intended terminal ports allow, typically in the 26- to 29-foot range. Hull depth is selected to provide the desired draft and satisfy statutory

freeboard requirements. Depth of the double bottom is kept low to maximize cargo space.

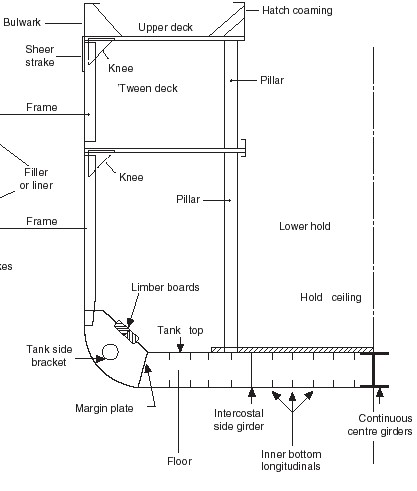

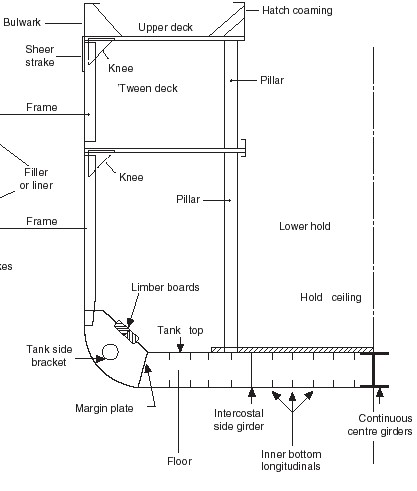

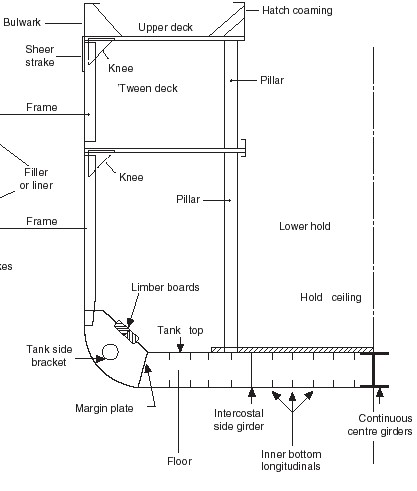

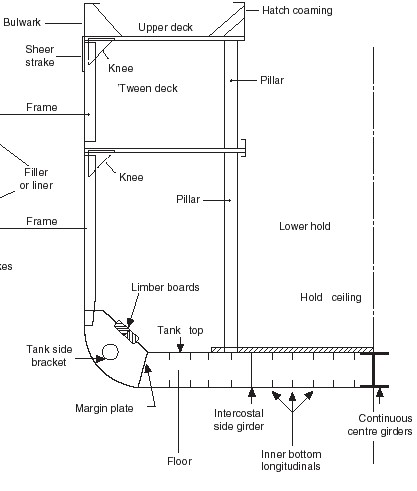

Fig:General cargo ships midship cross section

One or more ’tween decks may be fitted to facilitate flexibility in cargo loading

and unloading, cargo segregation, and to improve stability. There may be

watertight doors in the bulkheads on the ’tween decks levels. Denser cargoes are

carried in the lower holds with high stowage factor products normally stowed in

the ’tween decks. Refrigerated spaces may be built into the ’tween decks.

Tramps are designed to carry a wide variety of commodities while liners may be

designed for a specific trade. Ship designs for a specific trade strive for "full and

down" operation; the ship’s freeboard is down to her loadline with cargo cubic

fully occupied.

For a given trade, hold spaces are usually designed so that the

ratio of bale cubic to deadweight is 10 to 15 percent greater than the overall

stowage factor of the goods carried to allow for more rapid cargo handling and

broken stowage – the spaces between and around cargo units, including dunnage,

and spaces not available for cargo stowage because of physical obstructions or

ventilation and access requirements.

Holds are sized and provided with cargo

gear to limit the amount of cargo cubic per stevedore gang to about 60,000 cubic

feet; holds in the midbody are therefore usually shorter than those nearer the ends

of the ship. The conflict between the desire to shorten holds and the length

required by cargo gear and hatches sometimes dictates the assignment of midships

spaces to machinery or to fuel, cargo, or ballast deep tanks rather than holds.

Hatches are as large as possible without compromising hull strength (the main or

second deck is normally the strength deck) to reduce the requirement for

horizontal movement of cargo within the holds. Hatches served by two sets of

cargo gear generally measure 20 by 30 feet or larger. Hatches on older ships are

generally smaller than those on newer ships.

Hatches are surrounded by

coamings to reduce the risk of flooding in heavy seas. Covers are usually

constructed of steel (or wood on older vessels). The main deck plating between

hatches is not effective in providing longitudinal strength, and is sized to carry

fairly light local loads. The deck plating outboard the hatches is therefore much

heavier, often exceeding five-eighths inch in thickness.

Cargo gear is designed for speed and flexibility for handling breakbulk, palletized, or container cargo. Various combinations of derricks,

winches, and deck cranes are used for the handling of cargo. Cranes are fitted on many vessels to reduce manpower requirements. Some ships

have special heavy-lift derricks that may serve one or more holds. Booms are rigged for either yard and stay (burton) or swinging-boom

operation.

Various combinations of derricks, winches and deck cranes are used for the

Handling of cargo.

Basic Design of the Cargo Ship - Economic factors designing a new ship

The term “general (multipurpose) cargo ships” covers many

different ship designs that do not fit into other more specialised

cargo ship types. Thus, general cargo ships are not specialised

for transport of only dry bulks, only containers or only heavy-lift

cargoes, but they have flexibility to carry any of these cargo types.

General cargo ships are the world’s most numerous ship types,

excepting fishing vessels. Thus, in the year 2002 their share in the

overall world merchant fleet amounted to about 37% in numbers

and to about 11% in dwt.

The average deadweight of the world fleet of general cargo

ships is about 5600 dwt. Larger vessels, up to about 30000 dwt are

intended to carry break-bulk cargo (bagged, boxed and palletised

cargo) or containers, while small general cargo ships, usually

below 5000 dwt are mostly found as flexible solutions for many

dry-cargo types in shortsea shipping.

The concern for structural safety of general cargo ships

follows from the fact that during the period from 1995 to 2000

approximately 90 losses of these ships per year occurred, which

in other words means one ship every 4 days, with 170 fatalities

per year. Even 42% of losses of all merchant ships belong to general

cargo ships and similar percentage is valid also for fatality

experience. Despite these figures, general cargo ships are not

considered in publicity as risky ships, probably because general

cargo ship accidents are not as spectacular as for example accidents

of oil tankers Erika or Prestige .

There are several reasons for poor statistical records of general

cargo ships. Ship ages, inappropriate maintenance, poor quality

in operation of these ships and defi ciencies in design are some of

the main causes of a large number of accidents. Smaller general

cargo ships are particularly vulnerable to collision and grounding

accidents because of their frequent operation in inland waterways

and coastal waters.

The general cargo ship consists of as large a clear open cargo-carrying space as possible,

together with the facilities required for loading and unloading the cargo.

Access to the cargo storage areas or holds is provided by openings in the deck called

hatches. Hatches are made as large as strength considerations will allow to reduce

horizontal movement of cargo within the ship.

Hatch covers of wood or steel, as in most modern ships, are used to close the hatch

openings when the ship is at sea. The hatch covers are made watertight and lie upon

coamings around the hatch which are set some distance from the upper or weather deck

to reduce the risk of flooding in heavy seas.

One or more separate decks are fitted in the cargo holds and are known as tween decks.

Greater flexibility in loading and unloading, together with cargo segregation and

improved stability, are possible using the tween deck spaces.

Various combinations of derricks, winches and deck cranes are used for the

Handling of cargo.

Designing a new cargo ship

The economic factor is of prime importance in designing a merchant

ship. An owner requires a ship which will give him the best possible

returns for his initial investment and running costs. This means that the

final design should be arrived at taking into account not only present

economic considerations, but also those likely to develop within the life

of the ship.

With the aid of computers it is possible to make a study of a large number

of varying design parameters and to arrive at a ship design which is not

only technically feasible but, more importantly, is the most economically

efficient.

Fig:General cargo ships midship cross section

The initial design of a ship generally proceeds through three stages: concept;

preliminary; and contract design. The process of initial design is often

illustrated by the design spiral which indicates that given the

objectives of the design, the designer works towards the best solution

adjusting and balancing the interrelated parameters as he goes.

A concept design should, from the objectives, provide sufficient information

for a basic techno-economic assessment of the alternatives to be made.

Economic criteria that may be derived for commercial ship designs and

used to measure their profitability are net present value, discounted cash

flow or required freight rate. Preliminary design refines and analyses the

agreed concept design, fills out the arrangements and structure and aims

at optimizing service performance. At this stage the builder should have

sufficient information to tender. Contract design details the final arrangements

and systems agreed with the owner and satisfies the building

contract conditions.

Total design is not complete at this stage, it has only just started, postcontract

design entails in particular design for production where the

structure, outfit and systems are planned in detail to achieve a cost and

time effective building cycle. Production of the ship must also be given

consideration in the earlier design stages, particularly where it places

constraints on the design or can affect costs.

Ship Construction

The steel used in shipbuilding is mainly mild steel with 0.15-0.23% carbon content. Five grades of mild steel (A-E) are used ,manufactured, inspected, and tested under certain conditions. Finished steel is stamped by the classification societies.

High tensile steel is developed to have higher toughness,ductility, weldability, and strength.

This is developed by addition element such as vanadium, chromium, nickel, and Niobium.

Aluminum Alloys

Aluminum use in shipbuilding has increased due to the lighter weight (1/3 weight of steel). This

reduction of weight in the upper structure of the ship results in an improve of the ship stability.

Aluminum has a good resistance to corrosion. The main disadvantage of Aluminum is the high

cost.

Aluminum section are formed by extrusion. A special insulating arrangement is used when

joining steel to Aluminum.

Other useful articles :

- Assigning loadlines marks

Loadlines are marks punched into and painted on the sides of general cargo ships.The assigning of the vessels loadline and the issue of the Certificate is the

responsibility of the Marine Authority of the country. .

More .....

-

Cargo ships Loaded Condition

closely monitor the ship's condition during cargo

operations to ensure that if a significant deviation from the agreed loading/unloading

plan is detected all cargo and ballast operations must STOP..

More .....

-

Packing a container recommended method

Packing a container should always be done on level plane either on the ground,on a railcar, or on a trailer. In the case of a trailer, care should be taken to ensure the trailer cannot tip whilst being packed especially if a forklift truck is being used. If necessary the trailer should be propped. Brakes should be securely applied and wheels choked.

More .....

- Packing principles relating to cargo in containers

Where relevant, stowing should be carried out in a sequence which will permit

rapid checking and storage operations during and after unloading. Should the

consignment include cargo subject to customs pre-entry procedures, customs

examination would be made easier and unloading avoided if the cargo were

stowed at the end of the container by the door.

More .....

- Container Securing guidance

Containers have very little strength in any direction other than vertically

through the corner posts thus it is necessary to provide substantial support

to the containers when they are on the ship. Stowage of containers is with

their longer dimension fore and aft since the ship motion transmitted to

cargo is greater in rolling than pitching and it is therefore prudent to limit

any possible cargo movement within the container to the shorter transverse

dimension.

More .....

- Trim and stability booklet for cargo ships

Contain either curves of form or hydrostatic tables and stability and trim characteristics for various conditions of loading

.

More .....

- Broken stowage? Cargo ships guideline

The access shall be separate from the hatchway opening, and shall be by a stairway if possible. A fixed ladder, or a line of fixed rungs, shall have no point where they fill a reverse slope

.

More .....

-

Ship type, design and facilities for cargo

Cargo gear is designed for speed and flexibility for handling breakbulk, palletized, or container cargo. Various combinations of derricks,

winches, and deck cranes are used for the handling of cargo. Cranes are fitted on many vessels to reduce manpower requirements. Some ships

have special heavy-lift derricks that may serve one or more holds. Booms are rigged for either yard and stay (burton) or swinging-boom

operation.

More .....

- Cargo ships structural plans- how to use them

Structural plans, sometimes called scantlings plans, show dimensions of the ships framing and plating. The midships section drawing, generally available for all ships

More .....

Machinery system main info pages

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship employment

||

Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||